AI-Driven Battery Recycling Breakthrough: 95% Material Recovery

Imagine a world where nearly every ounce of a used battery is reborn, fueling the next generation of electric vehicles and clean energy storage. That world just got a lot closer. In July 2025, researchers at the University of California, San Diego, unveiled an AI-powered battery recycling process that recovers an astonishing 95% of critical materials-lithium, cobalt, and nickel-from spent lithium-ion batteries. This isn't just a technical milestone; it's a potential turning point in the global fight against battery waste and climate change.

The Battery Waste Dilemma

Lithium-ion batteries are the backbone of our electric future, powering everything from smartphones to electric vehicles. But as demand soars-projected to hit 3.8 terawatt-hours by 2030-the world faces a mounting waste crisis. Less than 5% of these batteries are recycled today, leaving mountains of toxic waste and lost resources. Traditional recycling methods are inefficient, energy-hungry, and often recover just 60 to 70% of valuable materials. The environmental cost is staggering, with smelting and chemical leaching releasing significant greenhouse gases and hazardous byproducts.

How AI Changes the Game

The UC San Diego team's breakthrough, published in Nature Energy, harnesses the power of machine learning to transform battery recycling. Their AI model analyzes the chemical makeup of used batteries in real time, guiding automated shredders and chemical processors to extract materials with surgical precision. This approach slashes energy use by 40% and cuts greenhouse gas emissions by 35% compared to conventional methods. The result: a cleaner, more efficient process that recovers almost all the critical elements needed for new batteries.

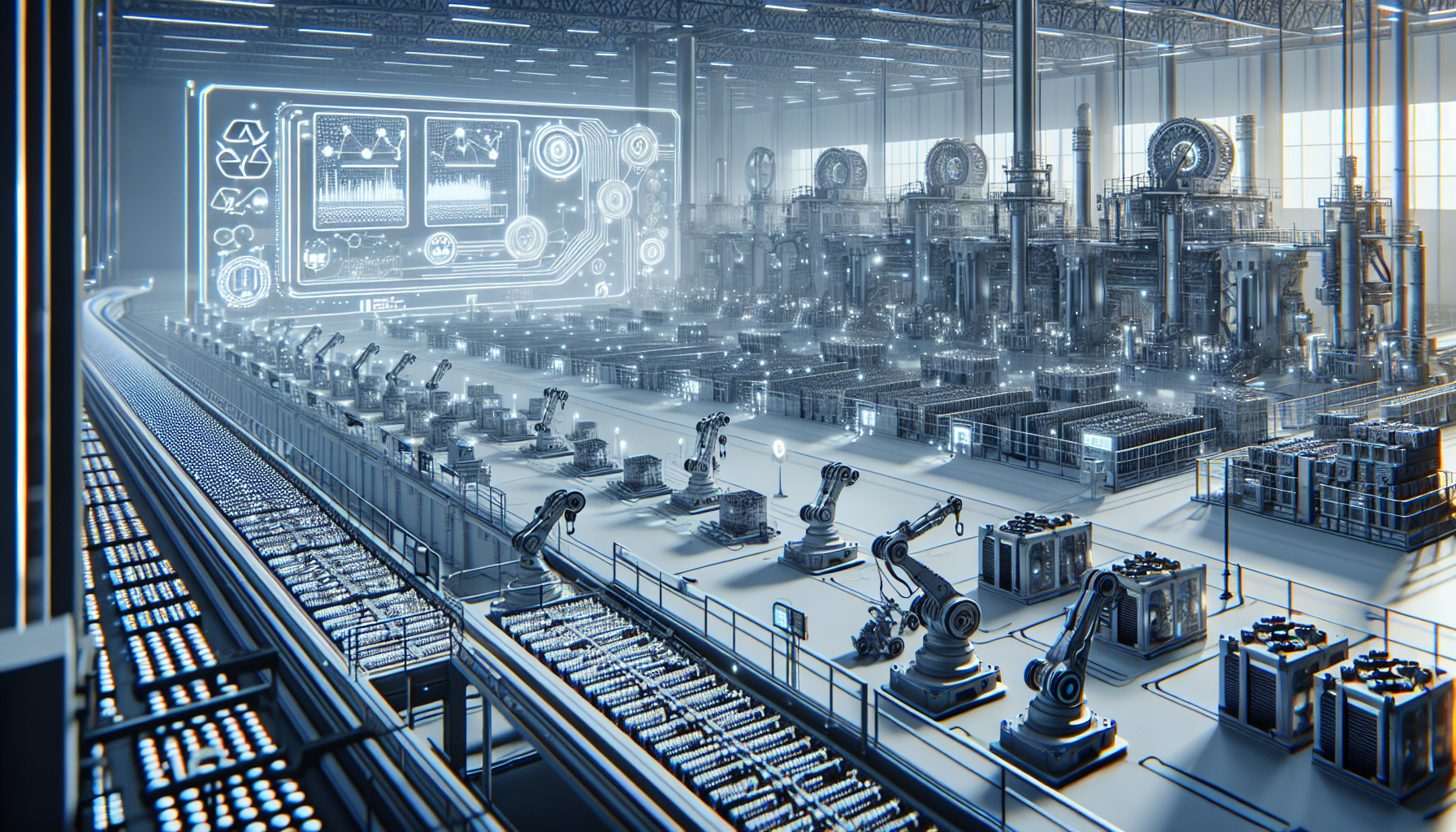

Inside the Process: Smarter, Cleaner, Faster

At the heart of this innovation is a blend of robotics and AI. Used batteries are first mechanically shredded, breaking them down into their core components. The AI system then scans and sorts the fragments, identifying the optimal chemical treatments for each batch. This real-time analysis means less waste, fewer contaminants, and higher purity in the recovered materials. Early trials have already processed 500 kilograms of batteries daily, with plans to scale up rapidly.

Industry Impact and Real-World Potential

Experts are taking notice. Dr. Emma Chen, a battery recycling specialist at Stanford, calls the technology "a game-changer for the circular economy." If adopted at scale, it could recycle up to 1.2 million tons of batteries annually by 2030, dramatically reducing the need for new mining and the environmental damage it causes. The process also aligns with global climate goals, offering a practical path to decarbonize the battery supply chain.

Challenges on the Road to Scale

Of course, no breakthrough is without hurdles. Building the AI infrastructure requires significant upfront investment, and the diversity of battery designs complicates automated sorting. Standardization across manufacturers could help, but that will take time and policy support. Mark Thompson, a supply chain analyst at BloombergNEF, notes, "The tech is promising, but scaling it globally will require more than just innovation-it needs collaboration and commitment from industry and governments alike."

A Glimpse Into the Future

The UC San Diego team is already partnering with recycling firms to pilot the technology in real-world settings. If these early successes continue, the process could set a new global standard for battery recycling-one that's not just efficient, but truly sustainable. Imagine a future where every battery is part of a closed loop, powering progress without polluting the planet.

The next time you plug in your EV or charge your phone, consider the journey of the battery inside-and the possibility that, thanks to AI, its story may never truly end.