Soft Robots, Hard Problems: The Durability Dilemma

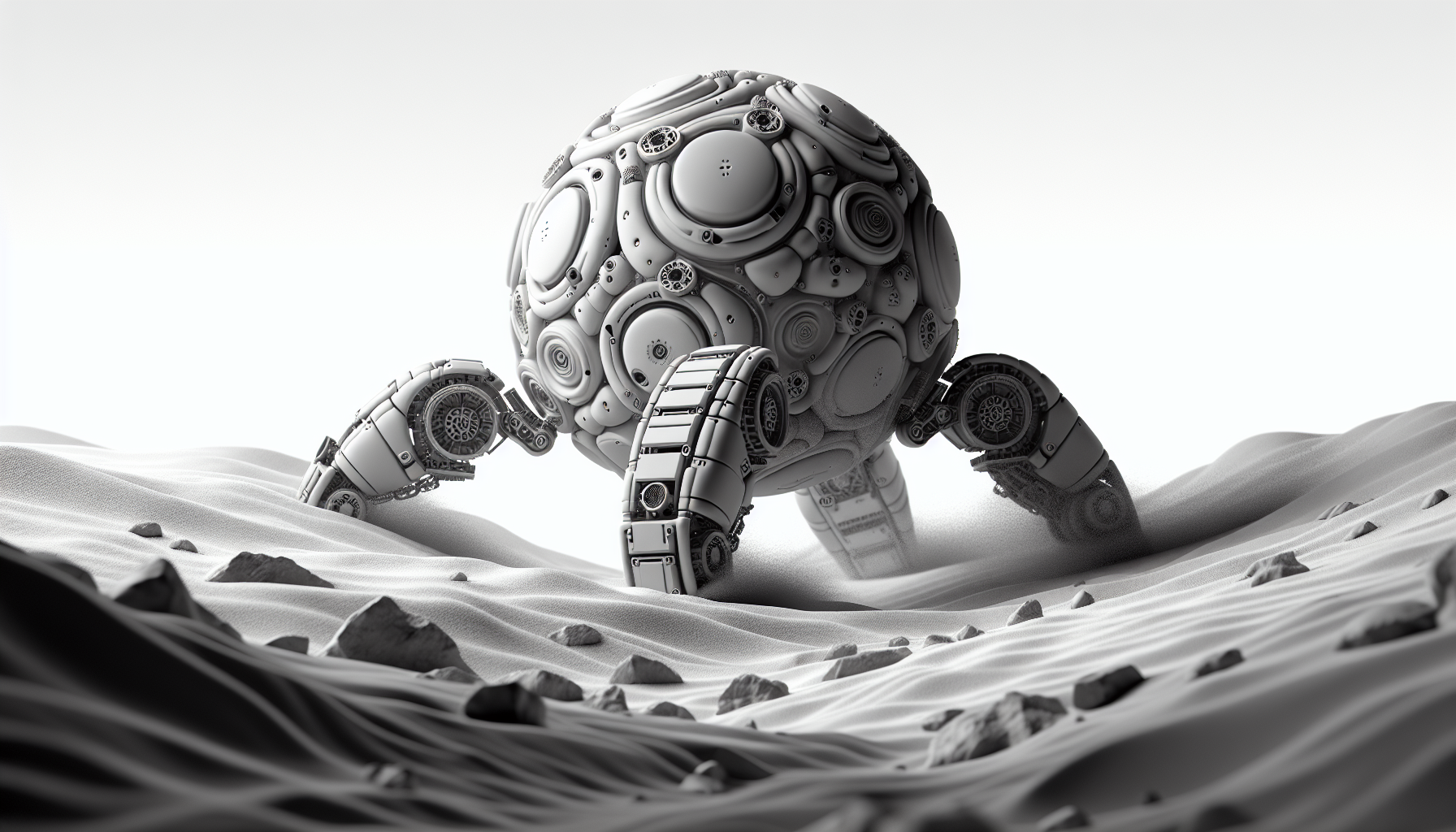

Imagine a robot that can squeeze through a pipe, survive a furnace, and patch itself up after a scrape. For years, this has been the dream-and the frustration-of soft robotics. Flexible machines have dazzled researchers with their gentle touch and adaptability, but their Achilles' heel has always been fragility. Now, a new material from MIT, called FlexiDur, is poised to change the game.

The Breakthrough: FlexiDur's Secret Sauce

On July 10, 2025, MIT researchers unveiled FlexiDur, a polymer composite that blends the stretchiness of silicone with the toughness of nanoscale ceramics. This hybrid material doesn't just bend and twist-it endures. FlexiDur shrugs off temperatures up to 250C and withstands pressures ten times greater than atmospheric, all while keeping its shape-memory abilities intact.

What sets FlexiDur apart isn't just its resilience. It can "heal" itself, repairing micro-tears that would sideline other soft robots. In lab tests, robots made from FlexiDur navigated tight industrial spaces and manipulated objects in simulated deep-sea and furnace conditions. The result? A lifespan up to three times longer than previous soft robotics materials.

Why Durability Matters: From Surgery to the Seafloor

Soft robots have always excelled at tasks that require a gentle touch-think surgical assistance or handling fragile goods. But their vulnerability to heat, pressure, and wear has kept them out of the world's toughest jobs. FlexiDur changes that equation. Suddenly, robots can venture into hazardous environments, from the crushing depths of the ocean to the scorching heat of manufacturing plants.

Dr. Elena Martinez, the project's lead, puts it simply: "FlexiDur opens the door to applications in hazardous environments, from deep-sea exploration to high-temperature manufacturing." The potential is vast. Imagine robotic assistants in surgery that can adapt to complex anatomy, or inspection bots crawling through oil rigs, undeterred by heat or pressure.

The Business Case: Cost, Value, and the Road Ahead

The global soft robotics market is booming, expected to jump from $1.2 billion in 2024 to $6.3 billion by 2030. FlexiDur could accelerate this growth, especially in sectors where both adaptability and toughness are non-negotiable. However, there's a catch: FlexiDur costs about 40% more to produce than standard materials, thanks to its ceramic reinforcements.

Critics worry this price tag could slow adoption. But proponents argue that the math changes when you factor in FlexiDur's longevity and self-healing. Fewer breakdowns mean less downtime and lower maintenance costs. Dr. Liam Chen, a robotics consultant, calls it "a game-changer" for industries where reliability is everything.

How FlexiDur Works: A Closer Look

At the heart of FlexiDur is a clever combination of silicone-based polymers and nanoscale ceramic particles. The silicone gives the material its flexibility, while the ceramics provide strength and resistance to heat and pressure. When the material is damaged, its molecular structure allows it to "zip" itself back together, much like self-healing skin.

This isn't just theory. In one test, a FlexiDur robot was punctured, then exposed to high temperatures. Within minutes, the material sealed itself, and the robot continued its task. This self-repair ability could be a game-changer for robots operating in places where human intervention is impossible or dangerous.

What's Next: From Lab to Life

MIT's team is already working with industry partners to put FlexiDur through its paces in real-world settings. By late 2026, we could see these shape-shifting, self-healing robots in factories, hospitals, and even the ocean's depths. The journey from fragile prototypes to robust, adaptable machines is nearly complete.

The promise of soft robotics has always been about blending the best of both worlds: the adaptability of living tissue with the reliability of machines. With FlexiDur, that promise is closer than ever. The next time you see a robot squeeze through a gap or survive a blast of heat, remember-it's not just smart design, it's a material revolution.

Sometimes, the softest touch is also the toughest.